Description

KEY FEATURES:

With autofocus system, thin and thick metal sheets can be cut with the best quality.

One-piece welded body, capable of achieving a very high acceleration.

Low operating cost and low energy consumption.

Excellent cutting results on all types of material. High quality components recognized worldwide.

Automatic sheet metal loading and unloading system.

Modern and compact design. Dynamic structure and easy to use.

SPECIFICATIONS:

Cutting Area: 3000 x 1500 mm.

Laser Power: l 000W 2000W 3000W 300000 W.

Positioning Accuracy: ±0.03 mm. Maximum X,Y Axis Speed: 120 m/min.

Maximum X,Y Axis Acceleration: l .2G, l .5G l .7G

2G3G4G.

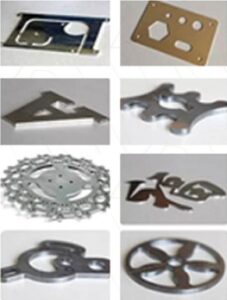

APPLICATIONS:

Automotive manufacturing, office furniture, electrical industry, chassis cabinets, elevator manufacturing, kitchenwareJldecorative curtain walls, machinery manufacturing, mold industry, rail transportation, medical equipment, office furniture.

OTHER:

WASTE SHEET SEPARATION SYSTEM:

Separating used part from main sheet was never so easy. With Dener Camera System you can separate waste part directly from screen.

REAL TIME NOZZLE STATUS:

Nozzle status is displayed on the screen. If the nozzle losses its circular shape change nozzle message is displayed on the screen.

REMOTE MACHINE MONITORING:

The machine can be accessed remotely, cutting can be monitored and problems solved. Thanks to 4 cameras available on the machine.

Since 1963

Since 1963

The Precitec cutting head is the world leader in fiber laser heads. Our dynamic laser

The Precitec cutting head is the world leader in fiber laser heads. Our dynamic laser